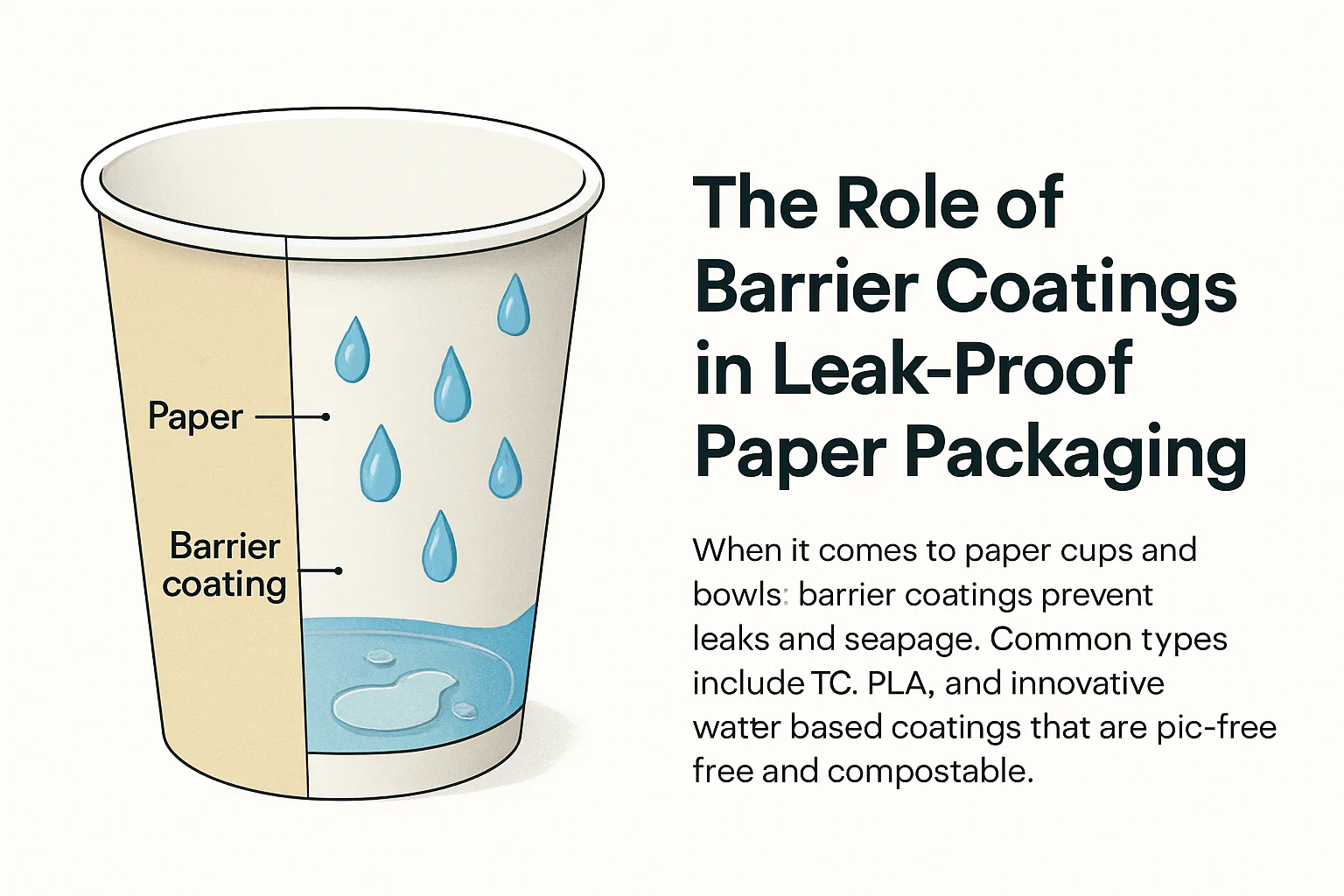

When it comes to paper cups and bowls, barrier coatings are the unsung heroes that keep your drink hot, your soup secure, and your salad oil-free. Without them, liquids and grease would quickly seep through the paper. In this article, we’ll explore how barrier coating paper cups work, the different types available, and why the right coating matters for both performance and sustainability.

Why Barrier Coatings Are Essential

Paper is naturally absorbent. While this is ideal for some applications, it’s a problem when packaging food or drinks. Barrier coatings create a thin protective layer on the paper surface that:

Prevents leaks and seepage

Improves heat resistance

Enhances durability and rigidity

Preserves the food’s taste and quality

Without a proper barrier, paper cups would become soggy, lose shape, and compromise the customer experience.

Common Types of Barrier Coatings

- Polyethylene (PE) Coating

A petroleum-based plastic layer that offers excellent leak-proof performance. While durable, it is not biodegradable, which makes recycling and composting more challenging.

2. Polylactic Acid (PLA) Coating

A plant-based alternative to PE. It is compostable under industrial conditions but still faces limitations in recyclability and availability of composting facilities.

3. Water-Based Coating (Aqueous Coating)

The latest eco-friendly solution, water-based coatings are plastic-free, compostable, and recyclable. They deliver strong barrier protection without adding microplastics to the environment, making them ideal for eco-conscious foodservice businesses.

How Barrier Coating Paper Cups Are Made

The coating is applied to large rolls of paperboard before they are cut and formed into cups. The type of coating determines the heat and leak resistance of the final product. For example, water-based coated paper cups are suitable for both hot and cold drinks while remaining fully compostable.

Choosing the Right Barrier Coating

When selecting paper cups for your business, consider:

Type of food or drink (hot, cold, oily, acidic)

Environmental goals (compostable, recyclable, plastic-free)

Regulatory compliance (FDA, LFGB, EN13432, etc.)

At Tiptopak, we help our customers choose the most suitable coating to meet both performance requirements and sustainability commitments.

Barrier coatings may be invisible, but they make a huge difference in the functionality and eco-friendliness of paper cups and food containers. By choosing the right coating—especially innovative water-based options—businesses can provide reliable, leak-proof packaging while reducing environmental impact.

Looking for sustainable, high-performance paper cups? Contact Tiptopak to explore our full range of barrier coating paper cups designed for today’s foodservice needs.